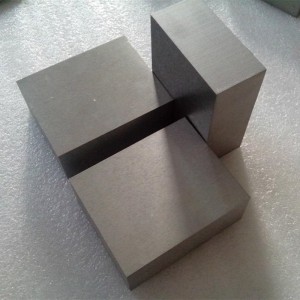

Nyiaj tungsten alloy

Silver tungsten alloy yog ib qho kev sib xyaw ua ke ntawm ob qho hlau zoo kawg nkaus, nyiaj thiab tungsten, uas muaj cov khoom tshwj xeeb thiab kev siv.

Cov alloy sib txuas cov hluav taws xob zoo heev ntawm cov nyiaj nrog lub siab melting point, hardness, thiab hnav tsis kam ntawm tungsten. Qhov no ua rau nws tsim nyog rau ntau yam kev thov hauv kev siv hluav taws xob thiab tshuab.

Hauv kev lag luam hluav taws xob, nyiaj tungsten alloy yog siv rau hauv kev sib cuag hluav taws xob thiab cov keyboards. Nws muaj peev xwm tiv taus qhov kub thiab txias thiab arcing ua rau nws ntseeg tau hauv cov khoom tseem ceeb no. Piv txwv li, nyob rau hauv high-power hluav taws xob systems, qhov twg tam sim no ntws yog tseem ceeb thiab cov kev pheej hmoo ntawm overheating yog siab, kev siv cov nyiaj tungsten alloy ua kom zoo thiab muaj kev nyab xeeb.

Nyob rau hauv lub mechanical realm, nws pom daim ntawv thov nyob rau hauv cov cuab yeej thiab tuag vim nws hardness thiab durability. Cheebtsam ua los ntawm cov hlau no tuaj yeem tiv taus kev ntxhov siab ntawm cov neeg kho tshuab thiab cov khoom siv abrasive, ua kom lawv lub neej ntev thiab txhim kho kev ua haujlwm.

Kev tsim cov nyiaj tungsten alloy feem ntau suav nrog cov txheej txheem nyuaj kom ua tiav qhov xav tau muaj pes tsawg leeg thiab microstructure. Qhov no ua kom pom qhov sib npaug ntawm cov khoom siv rau cov ntawv thov tshwj xeeb.

Kev tshawb fawb thiab kev loj hlob nyob rau hauv lub tshav pob ntawm cov nyiaj tungsten alloys txuas ntxiv mus, qhib kev muaj peev xwm tshiab thiab txhim kho. Cov kws tshawb fawb thiab engineers niaj hnub tshawb nrhiav txoj hauv kev los txhim kho nws cov khoom thiab nthuav nws cov ntawv thov ntau yam.

Nyob rau hauv xaus, nyiaj tungsten alloy sawv ua ib tug ua pov thawj rau tib neeg ingenuity nyob rau hauv cov ntaub ntawv kev tshawb fawb, muab kev daws teeb meem rau ib co ntawm cov feem ntau nyuaj engineering thiab technologies teeb meem. Nws qhov tshwj xeeb ua ke ntawm cov khoom ua rau nws yog ib qho khoom siv tsis tseem ceeb hauv ntau qhov kev lag luam, tsim lub ntiaj teb niaj hnub nrog nws qhov muaj peev xwm thiab muaj peev xwm.

Kev tsim cov nyiaj tungsten alloy:

Hmoov metallurgy:

Qhov no yog ib txoj hauv kev. Cov hmoov zoo ntawm cov nyiaj thiab tungsten yog sib xyaw hauv qhov xav tau proportions. Tom qab ntawd cov sib tov yog compacted nyob rau hauv siab siab los tsim ib tug ntsuab compact. Qhov kev cog lus no yog tom qab sintered ntawm qhov kub thiab txias kom fuse cov khoom ua ke thiab tsim cov khoom hlau. Piv txwv li, qee zaum, cov hmoov yuav raug milled ua ntej kom muaj kev sib xyaw ua ke.

Chemical Vapor Deposition (CVD):

Nyob rau hauv txoj kev no, gaseous precursors uas muaj nyiaj thiab tungsten yog nkag mus rau hauv cov tshuaj tiv thaiv chamber. Nyob rau hauv tshwj xeeb tej yam kev mob ntawm kub thiab siab, lub precursors react thiab tso rau ntawm ib tug substrate los tsim cov alloy txheej. Cov txheej txheem no tso cai rau kev tswj xyuas meej ntawm cov alloy muaj pes tsawg leeg thiab microstructure.

Electroplating:

Silver tungsten alloy tseem tuaj yeem tsim los ntawm electroplating. Ib qho tungsten substrate yog raus hauv ib qho electrolyte uas muaj nyiaj ions. Los ntawm kev siv hluav taws xob tam sim no, cov nyiaj tau muab tso rau ntawm qhov chaw tungsten, tsim cov txheej txheej hlau. Cov txheej txheem no tuaj yeem hloov kho kom ua tiav cov thicknesses sib txawv thiab cov txheej txheem ntawm cov txheej txheem alloy.

Sinter-HIP (Kub Isostatic Nias):

Cov hmoov sib tov yog thawj sintered thiab tom qab ntawd raug kub isostatic nias. Qhov no yuav pab tshem tawm cov porosity thiab txhim kho qhov ntom ntom thiab cov khoom siv kho tshuab ntawm cov ntaub ntawv alloy.

Kev xaiv ntawm txoj kev fabrication nyob ntawm ntau yam xws li cov khoom xav tau ntawm qhov kawg alloy, cov duab thiab qhov loj ntawm cov khoom yuav tsum tau tsim, thiab cov nplais ntau lawm. Txhua txoj kev muaj nws qhov zoo thiab kev txwv, thiab feem ntau, kev sib xyaw ua ke ntawm cov txheej txheem no yuav raug ua haujlwm kom ua tiav cov txiaj ntsig zoo tshaj plaws.

Silver tungsten alloy muaj ntau daim ntawv thov tshwj xeeb vim nws cov khoom tshwj xeeb:

Hluav taws xob tiv tauj:

● Nyob rau hauv high-voltage Circuit Court breakers, qhov twg nws muaj peev xwm lis loj tam sim no thiab nquag hloov tsis muaj qhov tseem ceeb hnav los yog degradation.

● Nyob rau hauv relays thiab contactors rau industrial tswj systems, muab kev ruaj ntseg hluav taws xob kev twb kev txuas thiab kev pab lub neej ntev.

Cov hluav taws xob:

● Rau kev siv hluav taws xob tawm hluav taws xob (EDM), qhov twg nws cov khoom siv hluav taws xob siab thiab ua haujlwm kom hnav kom ntseeg tau tias cov khoom tshem tawm tau zoo thiab muaj txiaj ntsig.

● Nyob rau hauv arc vuam electrodes, muab zoo cua sov dissipation thiab durability.

Aerospace Components:

● Nyob rau hauv qhov chaw ntawm cov tshuab dav hlau thiab cov tshuab siv dav hlau uas xav tau cov khoom siv nrog kev kub siab ua haujlwm thiab lub zog txhua yam.

Thermal Management:

● Raws li cov dab dej kub hauv cov khoom siv hluav taws xob, ua tau zoo thiab ua kom sov.

Tooling thiab Tuag:

● Rau stamping thiab kev ua haujlwm, tshwj xeeb tshaj yog nyob rau hauv daim ntawv thov uas siab hardness thiab hnav kuj tseem ceeb heev.

Cov hniav nyiaj hniav kub:

● Vim nws cov tsos zoo nkauj thiab ua haujlwm ntev, nws tuaj yeem siv rau hauv kev tsim cov khoom tshwj xeeb ntawm cov hniav nyiaj hniav kub.

Piv txwv li, nyob rau hauv kev lag luam tsheb, nyiaj tungsten alloy tiv tauj yog siv nyob rau hauv oob khab motors kom ntseeg tau tias kev pib ntawm lub cav nyob rau hauv ntau yam mob. Hauv kev sib txuas lus hauv kev sib txuas lus, nws tau ua haujlwm nyob rau hauv high-frequency switches los tswj cov teeb liab kev ncaj ncees thiab txo cov teeb liab poob.

Nyiaj Tungsten Alloy Properties

| Code No. | Tshuaj muaj pes tsawg leeg% | Mechanical zog | ||||||

| Ag | impurity≤ | W | Qhov ntom (g / cm3 ) ≥ | Hardness HB ≥ | RES (μΩ·cm) ≤ | Kev coj ua IAB/% ≥ | TRS/Mpa ≥ | |

| AW (30) | 70 ± 1.5 | 0.5 | Tshuav | 11.75 Nws | 75 | 2.3 | 75 | |

| AW (40) | 60 ± 1.5 | 0.5 | Tshuav | 12.40 Nws | 85 | 2.6 | 66 | |

| AW (50) | 50 ± 1.5 | 0.5 | Tshuav | 13.15 Nws | 105 | 3.0 | 57 | |

| AW (55) | 45 ± 2.0 | 0.5 | Tshuav | 13.55 Nws | 115 | 3.2 | 54 | |

| AW (60) | 40 ± 2.0 | 0.5 | Tshuav | 14.00 Nws | 125 | 3.4 | 51 | |

| AW (65) | 35 ± 2.0 | 0.5 | Tshuav | 14.50 Nws | 135 | 3.6 | 48 | |

| AW (70) | 30 ± 2.0 | 0.5 | Tshuav | 14.90 Nws | 150 | 3.8 | 45 | 657 ib |

| AW (75) | 25 ± 2.0 | 0.5 | Tshuav | 15.40 Nws | 165 | 4.2 | 41 | 686 ib |

| AW (80) | 20 ± 2.0 | 0.5 | Tshuav | 16.10 Nws | 180 | 4.6 | 37 | 726 ib |