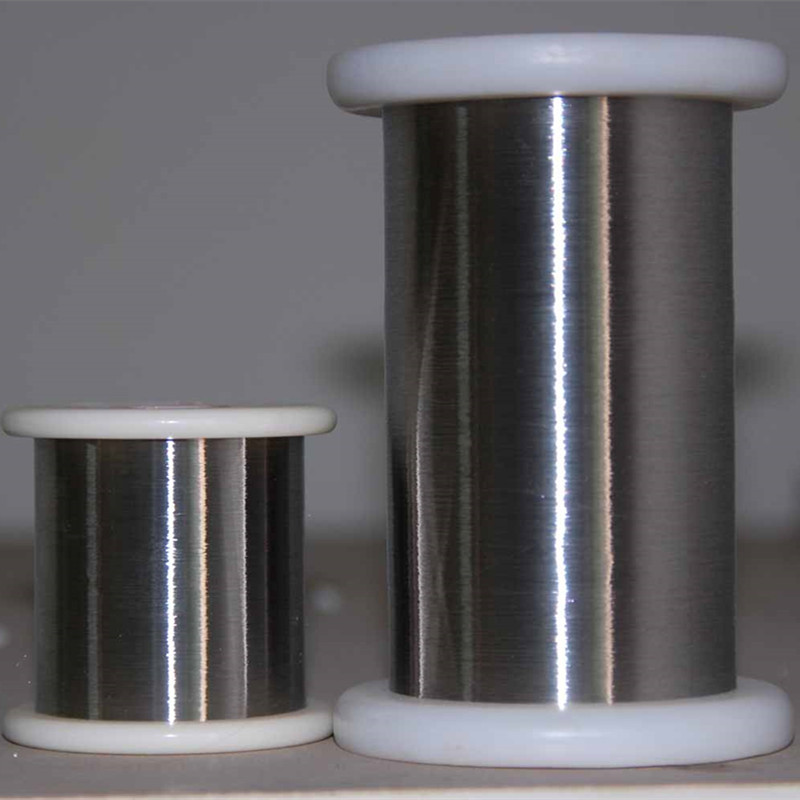

Nickel Chromium NiCr Alloy Hlau

0.03mm Hlau NiCr Alloy, 637 MPA Nickel Chromium Cua Sov Hlau, Ni90Cr10 NiCr Alloy

Ni90Cr10 yog ib qho austenitic nickel-chromium alloy haum rau kev siv kub txog li 1250 ° C. Cov ntsiab lus chromium siab (30% nyob rau hauv nruab nrab) muab lub neej zoo heev, tshwj xeeb tshaj yog nyob rau hauv cov ntawv thov cub tawg, nws yog feem ntau siv hauv vape, ua cov khoom cua sov.

Ni90Cr10 yog tus cwj pwm los ntawm kev ua haujlwm siab, zoo oxidation tsis kam, zoo ductility tom qab siv thiab zoo weldability. Alloy tsis raug rau "ntsuab rot" thiab yog qhov tshwj xeeb zoo rau kev txo qis thiab oxidizing cua.

Ni70Cr30 yog siv rau hluav taws xob cua sov ntsiab nyob rau hauv industrial furnaces. Cov ntawv thov yog: hluav taws xob thiab enamelling rauv, cia cov cua sov, cov cub tawg thiab cov kiln nrog cov cua hloov pauv.

Daim ntawv thov ntawm NiCr Alloy Hlau:

Nickel-chromium cov ntaub ntawv muaj qhov kub thiab txias zog thiab muaj zog plasticity.

Dav siv nyob rau hauv industrial hluav taws xob furnaces, khoom siv hauv tsev, far-infrared li.

Nickel-chromium thiab hlau, txhuas, silicon, carbon, sulfur thiab lwm yam khoom tuaj yeem ua rau cov hlau nickel-chromium alloy nrog siab tiv taus thiab kub tsis kam. Nws yog cov khoom siv hluav taws xob cua sov ntawm lub qhov cub hluav taws xob, hluav taws xob soldering hlau, hluav taws xob hlau, thiab lwm yam.

Qhov zoo ntawm Nickel-Chromium Hlau:

Qhov tsis kam yog qhov siab, cov txheej txheej saum npoo tau zoo oxidation tsis kam, thiab lub zog compressive yog khaws cia zoo dua li ntawm cov hlau-chromium-aluminium hlau nyob rau hauv qhov kub thiab txias, thiab kev ua haujlwm kub tsis yooj yim los tsim deformation. Nickel-chromium hlau muaj cov yas zoo deformation, zoo heev cov yam ntxwv thiab forge-muaj peev xwm, yooj yim los tsim thiab txheej txheem, yooj yim kho thiab nyuaj rau kev hloov hauv cov qauv. Tsis tas li ntawd, nickel-chromium hlau muaj emissivity siab, zoo corrosion kuj thiab ntev daim ntawv thov.

Nickel-chromium alloy kev ua haujlwm rooj

| Cov khoom siv ua haujlwm | Cr10 Ni90 | Cr20 Ni80 | Cr30Ni70 | Nc15Ni60 | Cr20Ni35 | Cr20Ni30 | |

| Kev sib xyaw | Ni | 90 | So | So | 55.0-61.0 Nws | 34.0-37.0 Nws | 30.0-34.0 Nws |

| Cr | 10 | 20.0-23.0 Nws | 28.0-31.0 Nws | 15.0-18.0 Nws | 18.0-21.0 Nws | 18.0-21.0 Nws | |

| Fe |

| ≤1.0 | ≤1.0 | So | So | So | |

| Qhov kub siab tshaj ℃ | 1300 | 1200 | 1250 | 1150 | 1100 | 1100 | |

| Melting point ℃ | 1400 | 1400 | 1380 | 1390 ib | 1390 ib | 1390 ib | |

| Qhov ceev g / cm3 | 8.7 ib | 8.4 | 8.1 | 8.2 | 7.9 ib | 7.9 ib | |

| Kev tiv thaiv |

| 1.09 ± 0.05 | 1.18 ± 0.05 | 1.12 ± 0.05 | 1.00 ± 0.05 | 1.04 ± 0.05 | |

| μΩ·m, 20 ℃ | |||||||

| Elongation ntawm rupture | ≥ 20 | ≥ 20 | ≥ 20 | ≥ 20 | ≥ 20 | ≥ 20 | |

| Tshwj xeeb kub |

| 0.44 ib | 0.461 ib | 0.494 ib | 0.5 | 0.5 | |

| J/g ℃ | |||||||

| Thermal conductivity |

| 60.3 | 45.2 ib | 45.2 ib | 43.8 ib | 43.8 ib | |

| KJ/mh ℃ | |||||||

| Coefficient ntawm kab expansion |

| 18 | 17 | 17 | 19 | 19 | |

| ib × 10-6 / | |||||||

| (20~1000 ℃) | |||||||

| Micrographic qauv |

| Austenite | Austenite | Austenite | Austenite | Austenite | |

| Cov khoom sib nqus |

| Nonmagnetic | Nonmagnetic | Nonmagnetic | Tsis muaj zog hlau nplaum | Tsis muaj zog hlau nplaum | |