Tungsten Copper WCu Kub dab dej

Kev piav qhia

tungsten tooj liab hluav taws xob ntim khoom muaj ob qho tib si tsis tshua muaj zog ntawm tungsten thiab cov thermal conductivity siab ntawm tooj liab. Dab tsi yog qhov tseem ceeb tshaj plaws yog tias nws cov thermal expansion coefficient thiab thermal conductivity tuaj yeem tsim los ntawm kev kho qhov sib xyaw ntawm cov khoom coj los yooj yim.

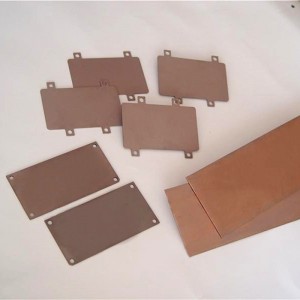

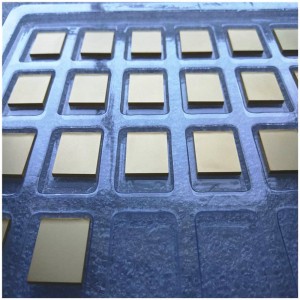

FOTMA siv high-purity thiab high-zoo raw cov ntaub ntawv, thiab tau txais WCu hluav taws xob ntim cov ntaub ntawv thiab cov khoom cua kub dab dej nrog kev ua tau zoo heev tom qab nias, high-temperature sintering thiab infiltration.

Qhov zoo ntawm Tungsten Copper (WCu) Cov Khoom Siv Hluav Taws Xob

1. Cov khoom siv tungsten tooj liab hluav taws xob ntim khoom muaj qhov hloov tau thermal expansion coefficient, uas tuaj yeem sib xyaw nrog cov substrates sib txawv (xws li: stainless hlau, valve alloy, silicon, gallium arsenide, gallium nitride, aluminium oxide, thiab lwm yam);

2. Tsis muaj sintering ua kom cov ntsiab lus ntxiv kom muaj cov thermal conductivity zoo;

3. Tsawg porosity thiab zoo huab cua nruj;

4. Zoo tswj qhov loj me, nto tiav thiab flatness.

5. Muab daim ntawv, tsim qhov chaw, kuj tuaj yeem ua tau raws li qhov xav tau ntawm electroplating.

Copper Tungsten Heat Sink Properties

| Khoom Qib | Tungsten Cov ntsiab lus Wt% | Qhov ceev g / cm3 | Thermal Expansion × 10-6CTE (20 ℃) | Thermal conductivity W / (M·K) |

| 90wc ua | 90 ± 2% | 17.0 Nws | 6.5 | 180 (25 ℃) / 176 (100 ℃) |

| 85wc ua | 85 ± 2% | 16.4 ib | 7.2 | 190 (25 ℃) / 183 (100 ℃) |

| 80wc ua | 80 ± 2% | 15.65 Nws | 8.3 | 200 (25 ℃) / 197 (100 ℃) |

| 75wc ua | 75 ± 2% | 14.9 Nws | 9.0 ib | 230 (25 ℃) / 220 (100 ℃) |

| 50wc ua | 50 ± 2% | 12.2 | 12.5 ib | 340 (25 ℃) / 310 (100 ℃) |

Daim ntawv thov ntawm tungsten tooj liab cua sov dab dej

Cov ntaub ntawv tsim nyog rau ntim nrog cov khoom siv hluav taws xob siab, xws li cov khoom siv hluav taws xob, cov hluav taws xob qis, thiab lwm yam .; high-kev ua tau zoo txhuas ncej; thermal tswj boards thiab radiators rau tub rog thiab pej xeem thermal tswj cov cuab yeej.