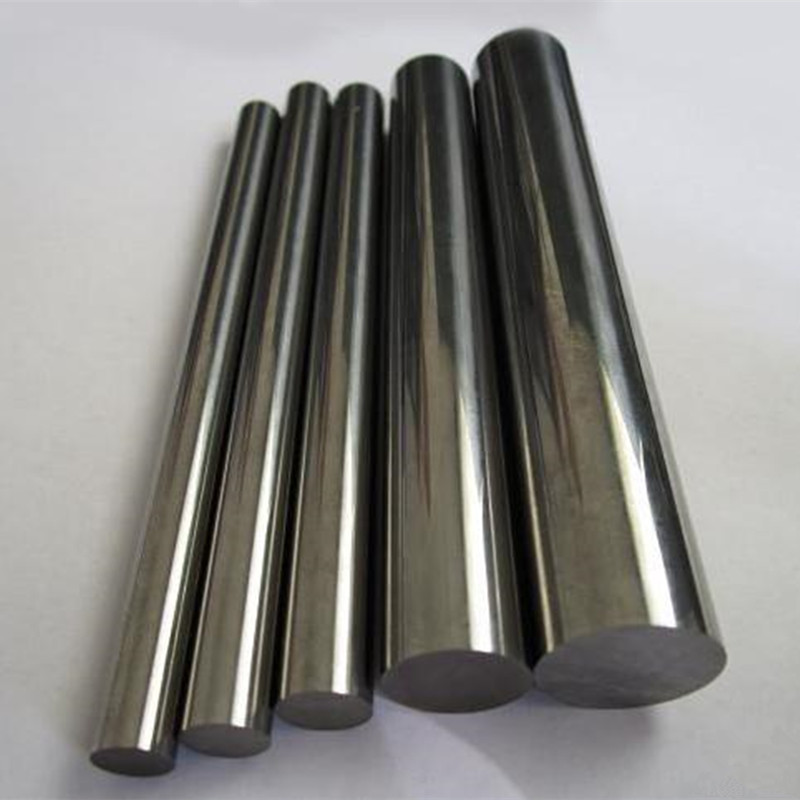

Tungsten Heavy Alloy Qws

Specifications

Tungsten Heavy Alloy Qib:

W90NiFe/W92.5NiFe/W93NiFe/W95NiFe/W97NiFe (Me ntsis sib nqus).

W90NiCu/W92.5NiCu/W93NiCu/W95NiCu/W97NiCu (Nonmagnetic).

Ceev:16.8-18.8g / cm3.

Nto:Machined & Hauv av.

Txheem:ASTM B777 Cov khoom lag luam

Txoj kab uas hla:5.0mm-80mm.

Ntev:50mm-350mm.

Tungsten High Density Alloy Advantages

High ceev (txog 65% denser dua Lead).

Cov ntaub ntawv denser muaj nyob (ntshiab Tungsten, Kub, platinum pab pawg hlau) tab sis lawv siv yog txwv los ntawm kev muaj, ua haujlwm thiab nqi.

Muab huab hwm coj qhov chaw ntim tsawg.

Concentrated hnyav qhov tseem ceeb qhov tseeb yog yuav tsum tau nyob rau hauv qhov chaw ntawm loj.

Qhov chaw ntawm qhov hnyav nyob rau hauv cov xwm txheej uas airflow muaj kev cuam tshuam loj heev.

Thermal Properties ntawm Tungsten Heavy Alloys

Siab softening kub.

Tsawg thermal conductivity thiab tsis tshua muaj coefficient ntawm expansion muab cov khoom muaj zog tiv thaiv thermal qaug zog.

Zoo heev soldering yaig tsis kam rau molten aluminium. Muaj zog ntawm qhov kub thiab txias nrog siab thermal stability.

Tungsten High Density Alloy Mechanical Properties

● High Young lub modulus ntawm elasticity. Tsis nkag siab thaum ntsib cov rog tseem ceeb, tsis zoo li Lead.

● Txawm tias lawv lub zog, lawv nyob twj ywm thiab tiv taus tawg.

● Lub hardness ntau ntawm cov alloys feem ntau yog 20-35 Hardness HRC.

High-Density Tungsten Raws li Alloy

| Hom alloy(%) | HD17 90W 6Ni 4Cu | HD17D 90W 7Ni 3Fe | HD17.5 92.5W 5.25Ni 2.25Fe | HD17.6 92.5W Balance Ni, Fe, Mo | HD17.7 93W Balance Ni, Fe, Mo | HD18 95W 3.5Ni 1.5Cu | HD18D 95W 3.5Ni 1.5 Fe | HD18.5 97W 2.1Ni 9Fe |

| MIL-T-21014 | Chav Kawm 1 | Chav Kawm 1 | Chav Kawm 1 | - | - | Chav kawm 3 | Chav kawm 3 | Chav Kawm 4 |

| SAE-AMS-T-21014 | Chav Kawm 1 | Chav Kawm 1 | Chav kawm 2 | - | - | Chav kawm 3 | Chav kawm 3 | Chav Kawm 4 |

| TIAB SA 7725 C | 7725c ua | 7725c ua | -- | -- | -- | -- | -- | -- |

| ASTM B777-87 Cov | Chav Kawm 1 | Chav Kawm 1 | Chav kawm 2 | - | - | Chav kawm 3 | Chav kawm 3 | Chav Kawm 4 |

| Hom ntom ntom(g / cc) | 17.1 | 17.1 | 17.5 Nws | 17.6 ib | 17.7 ib | 18 | 18 | 18.5 Nws |

| Hom ntom ntom(lbs / hauv 3) | 0.614 ib | 0.614 ib | 0.632 ib | 0.636 ib | 0.639 ib | 0.65 ib | 0.65 ib | 0.668 ib |

| Hom Hardness RC | 24 | 25 | 26 | 30 | 32 | 27 | 27 | 28 |

| Qhov kawg Tensile Strength Min(ksi) | 110,000 | 120,000 | 114,000 Nws | 120,000 | 125,000 ib | 110,000 | 120,000 | 123,000 Nws |

| 0.2% Offset Yield Strength Min(ksi) | 80,000 | 88,000 ib | 84,000 ib | 90,000 ib | 95,000 ib | 85,000 ib | 90,000 ib | 85,000 ib |

| Tsawg kawg % Elongation(1 "gage length) | 6 | 10 | 7 | 4 | 4 | 7 | 7 | 5 |

| Proportional Elastic txwv(PSI) | 45,000 ib | 52,000 ib | 46,000 ib | 55,000 ib | 60,000 | 45,000 ib | 44,000 ib | 45,000 ib |

| Modulus ntawm Elasticity(x 106 psi) | 40 x 106 | 45 x 106 | 47 x 106 | 52 x 106 | 53x106 ib | 45 x 106 | 50 x 106 | 53x106 ib |

| Coefficient ntawm Thermal Expansion x10-6/0C(20-400C) | 5.4 | 4.61 ib | 4.62 ib | 4.5 | 4.5 | 4.43 ib | 4.6 | 4.5 |

| Thermal conductivity(CGS units) | 0.23 | 0.18 | 0.2 | 0.27 ib | 0.27 ib | 0.33 ib | 0.26 | 0.3 |

| Hluav taws xob conductivity(% IACS) | 14 | 10 | 13 | 14 | 14 | 16 | 13 | 17 |

| Sib nqus | No | Me ntsis | Me ntsis | Me ntsis | Me ntsis | No | Me ntsis | Me ntsis |